What is the market prospect of non-standard design for measuring gauges and assembly fixtures?

The market prospects for non-standard design of measuring gauges and assembly fixtures are relatively broad, showing a good development trend. The following is a specific analysis:

Market demand continues to grow:

Driven by the upgrading of manufacturing industry: With the continuous development of high-end manufacturing, products are becoming increasingly diversified and complex, and traditional standard tools are unable to meet production needs. Non standard design can be customized for specific product characteristics such as shape, size, and material. In industries such as automotive and aerospace, it can ensure the accuracy and assembly quality of complex components, and is therefore favored by many manufacturing companies.

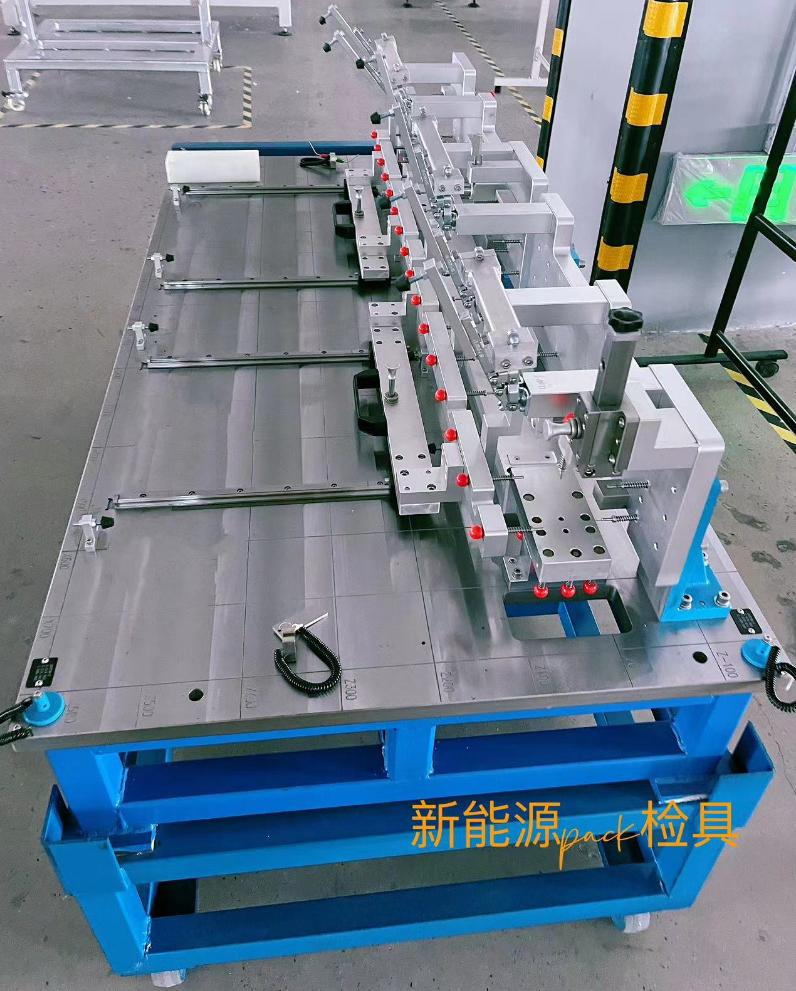

Driven by emerging industries: The rapid development of emerging industries such as new energy vehicles and 5G communication has put forward new demands for measuring tools and assembly fixtures. For example, in the production of new energy vehicles, the manufacturing of key components such as batteries and motors requires high-precision non-standard inspection tools, as well as customized assembly fixtures to ensure production efficiency and quality, providing new growth points for the market.

Technological development brings opportunities:

The trend towards intelligence: The widespread application of IoT, big data, and artificial intelligence technologies is driving the development of measurement tools towards intelligence. Intelligent gauges can achieve automatic measurement, data analysis, and quality control, improving production efficiency and detection accuracy. The market demand for such high-end non-standard gauges will continue to increase.

Automation upgrade: The advancement of automation technology makes assembly fixtures more efficient and intelligent. By introducing intelligent control systems and remote monitoring functions, non-standard automated assembly fixtures can achieve intelligent recognition and adjustment. This helps companies reduce labor costs, improve production speed and quality, and is in line with the development trend of "machines replacing people" in the manufacturing industry. The market outlook is optimistic.

Strong policy support: National strategies such as "Made in China 2025" provide strong support for the development of related industries. The "14th Five Year Plan for the Development of Intelligent Manufacturing" released by the National Development and Reform Commission proposes to vigorously develop the intelligent manufacturing equipment industry, and clearly points out the need to focus on breakthroughs in key core technologies and products such as precision measurement and testing equipment, creating a favorable policy environment for non-standard design and operation of measurement gauges and assembly fixtures.

Large space for import substitution: Currently, there are still some high-end products in the Chinese gauge market that rely on imports. But with the improvement of domestic enterprise technology, domestic gauge brands such as Huace Testing and AVIC Optoelectronics are gradually rising, occupying a large share in the mid to low end market and beginning to penetrate the high-end market. The space for import substitution is vast, which will promote the further development of the domestic non-standard design market.

However, this field also faces some challenges, such as fluctuations in raw material prices that may affect cost control and profitability, increased uncertainty in the international trade environment that may pose challenges to export business, and fierce competition within the industry, requiring companies to continuously increase research and development investment to cope with technological updates.

Please first Loginlater ~