How can non-standard design enterprises for measuring gauges and assembly fixtures improve their competitiveness?

To stand out in the fiercely competitive market, non-standard design enterprises for measuring gauges and assembly fixtures need to build core advantages from multiple dimensions such as technology, service, and management. Specifically, they can enhance their competitiveness from the following aspects:

1、 Strengthen technology research and innovation capabilities

Technology is the core competitiveness of non-standard design enterprises, and it is necessary to continuously break through technological barriers and form differentiated advantages

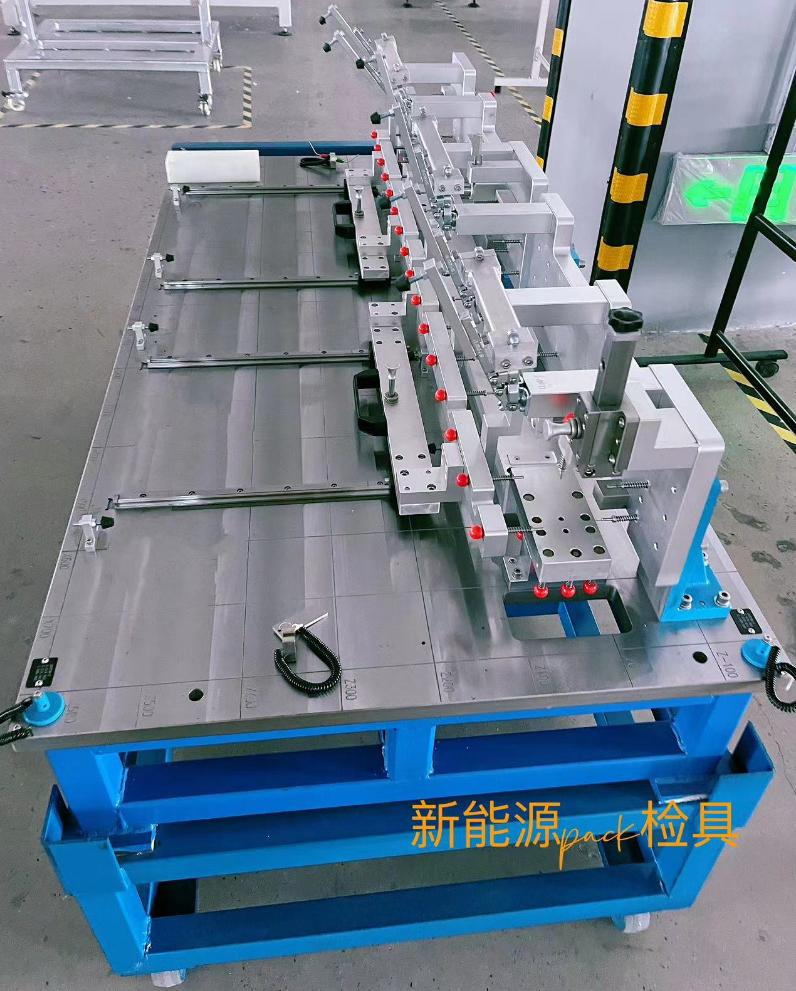

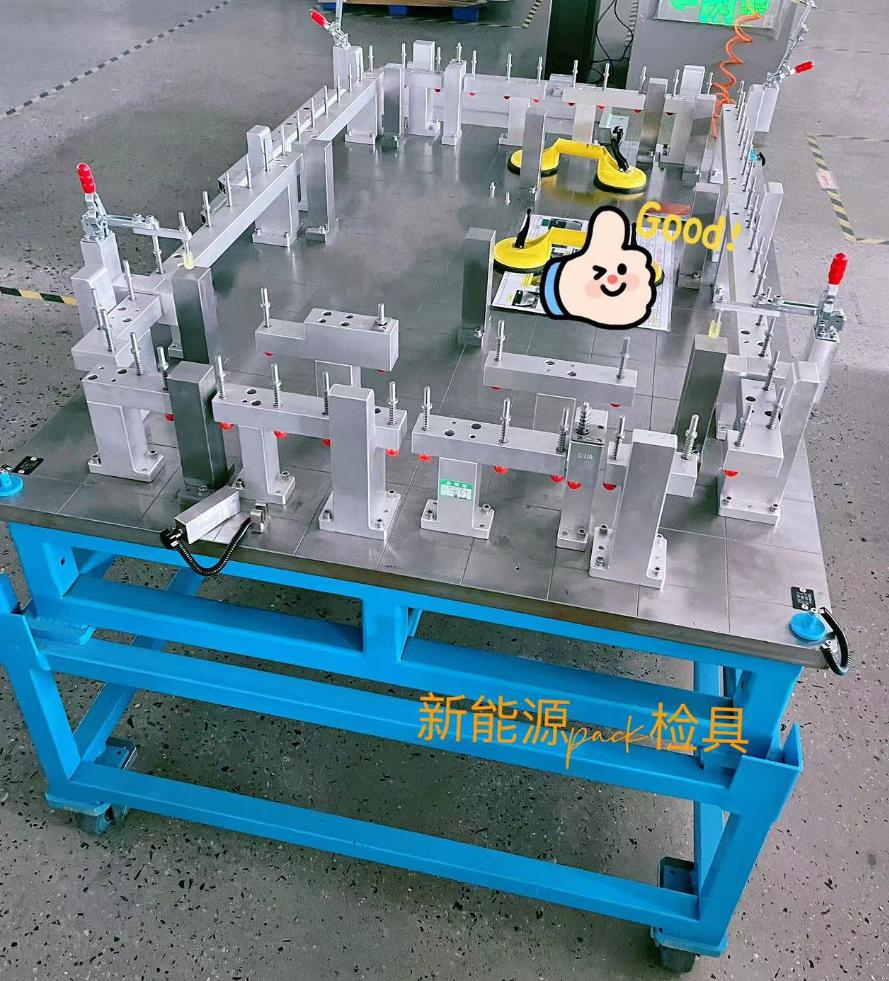

Deeply cultivating technology in segmented fields: focusing on the core needs of specific industries (such as automobiles, aerospace, and new energy), developing exclusive technologies for high-precision measurement and complex assembly scenarios. For example, customized gauges integrating pressure sensing and data analysis are developed for the sealing testing of new energy vehicle battery casings, forming a "specialized and refined" technology label in the industry.

Integrating cutting-edge technologies: introducing 3D modeling (such as SolidWorks, UG), finite element analysis (FEA), machine vision, Internet of Things (IoT) and other technologies to improve design efficiency and product performance. For example, using machine vision to achieve automated measurement and real-time data uploading of inspection tools, coupled with AI algorithms to automatically identify defects, to meet customers' demand for intelligent production.

Establish a technology iteration mechanism: set up a special R&D fund, regularly cooperate with universities and research institutions (such as jointly building laboratories with mechanical engineering colleges), track international cutting-edge technologies (such as German precision measurement technology and Japanese automated assembly processes), and ensure technological leadership.

2、 Optimize product quality and provide customized services

The core of non-standard design is "on-demand customization", which should be guided by customer needs and provide high-quality services throughout the entire chain from design to after-sales:

Precise docking requirements: In the early stage, we will go deep into the customer's production site, clarify the details of the requirements (such as measurement accuracy, production pace, environmental adaptability) through process analysis, sample testing, etc., to avoid the disconnection between design and reality. For example, when designing assembly fixtures for aerospace companies, it is necessary to consider the impact of high temperature and high pressure environments on materials and structures.

Strict control of production quality: high-precision machining equipment (such as five axis machining centers), high-quality materials (such as aviation grade aluminum alloy, wear-resistant steel), and quality system certifications such as ISO9001 and IATF16949 are used to ensure product stability. At the same time, establish a full process quality inspection mechanism (such as first article inspection and batch sampling) to reduce the risk of customer rework.

Provide value-added services: In addition to design and manufacturing, additional services such as installation and debugging, operator training, regular maintenance, and upgrading of old equipment are provided. For example, providing annual calibration services for inspection tools for automotive parts manufacturers, or quickly adjusting tooling structures based on customer product iteration needs.

3、 Cost reduction, efficiency improvement, and supply chain management

Control costs, improve delivery efficiency, and enhance market bargaining power while ensuring quality:

Optimize the design process: Adopt parametric design and modular components (such as universal fixtures and standard sensors) to reduce repetitive design workload and shorten the research and development cycle. For example, when designing gauges for products in the same series, sharing the basic framework and only replacing the measuring head can reduce costs by more than 30%.

Integrate supply chain resources: Establish long-term cooperation with high-quality raw material suppliers and outsourcing manufacturers, and reduce procurement costs through bulk procurement, joint development, and other methods. At the same time, establish a supply chain emergency mechanism (such as alternative suppliers) to avoid delivery delays caused by material shortages.

Promote digital management: Introduce ERP systems to manage orders, production, and inventory, use MES systems to monitor production progress, reduce manual errors through digital tools, and improve production efficiency. For example, by using order prioritization algorithms, ensure quick response to urgent orders.

4、 Focus on industry cultivation and customer stickiness

Non standard design has strong industry attributes and requires deep industry cultivation to establish brand awareness and enhance customer loyalty

Lock in segmented markets: Avoid being too big and too comprehensive, choose 1-2 advantageous industries (such as new energy vehicles and semiconductors) to deeply cultivate, accumulate industry experience and successful cases, and form an image of "industry experts". For example, focusing on the design of power battery pole piece inspection tools, we have become a core supplier for companies such as CATL and BYD.

Establish a customer case library: Show strength and enhance the trust of new customers through successful cases (such as improving detection efficiency by 50% and reducing defect rate by 20% for a certain enterprise). At the same time, regular follow-up visits to old customers are conducted to collect feedback and optimize products, forming a virtuous cycle of "cooperation feedback iteration".

Brand and reputation building: Enhance brand exposure through industry exhibitions (such as China International Industry Expo), technical seminars, and case studies on corporate websites. In addition, encourage customers to recommend new businesses (such as setting referral rewards) and expand the market through word-of-mouth communication.

5、 Addressing the challenges of talent and policy environment

Cultivate professional talents: form cross disciplinary teams (mechanical design, automation control, materials science, software engineering, etc.), solve the talent shortage problem through internal training, external recruitment (such as introducing senior engineers), and targeted training in cooperation with vocational colleges.

Leveraging policy dividends: Actively applying for qualifications such as high-tech enterprises and specialized, refined, and new "little giants", enjoying policy support such as tax reductions and R&D subsidies. At the same time, pay attention to policy guidance such as "Made in China 2025" and "14th Five Year Plan for the Development of Intelligent Manufacturing", and lay out areas supported by policies (such as intelligent testing and green manufacturing fixtures).

Please first Loginlater ~