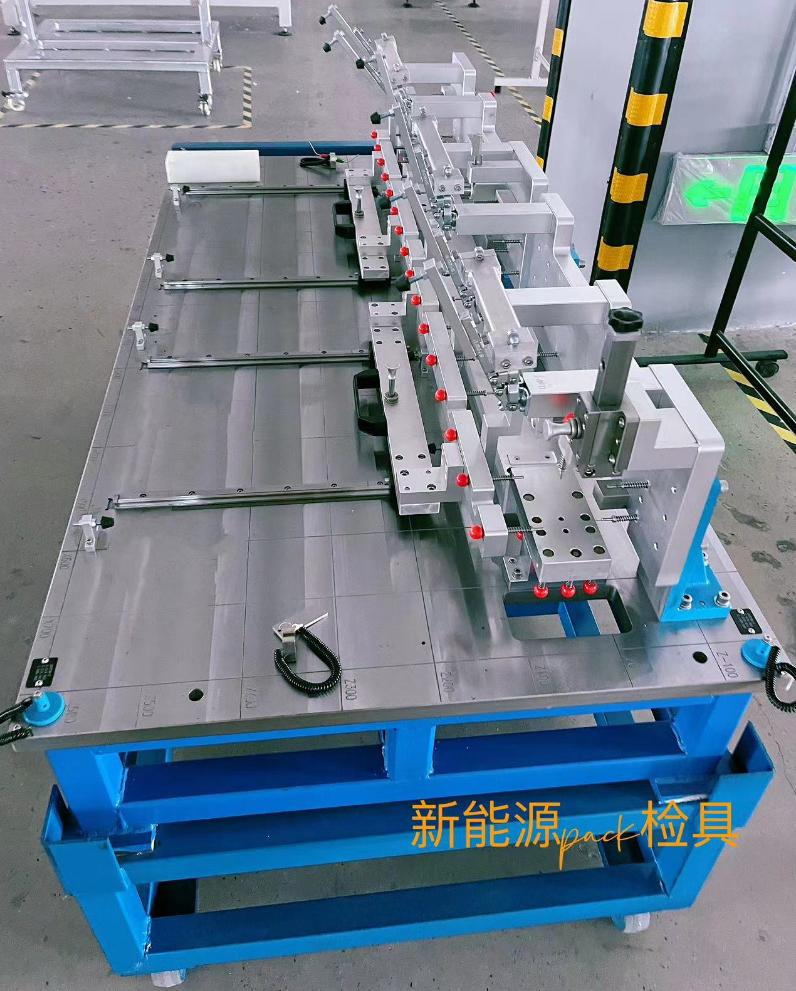

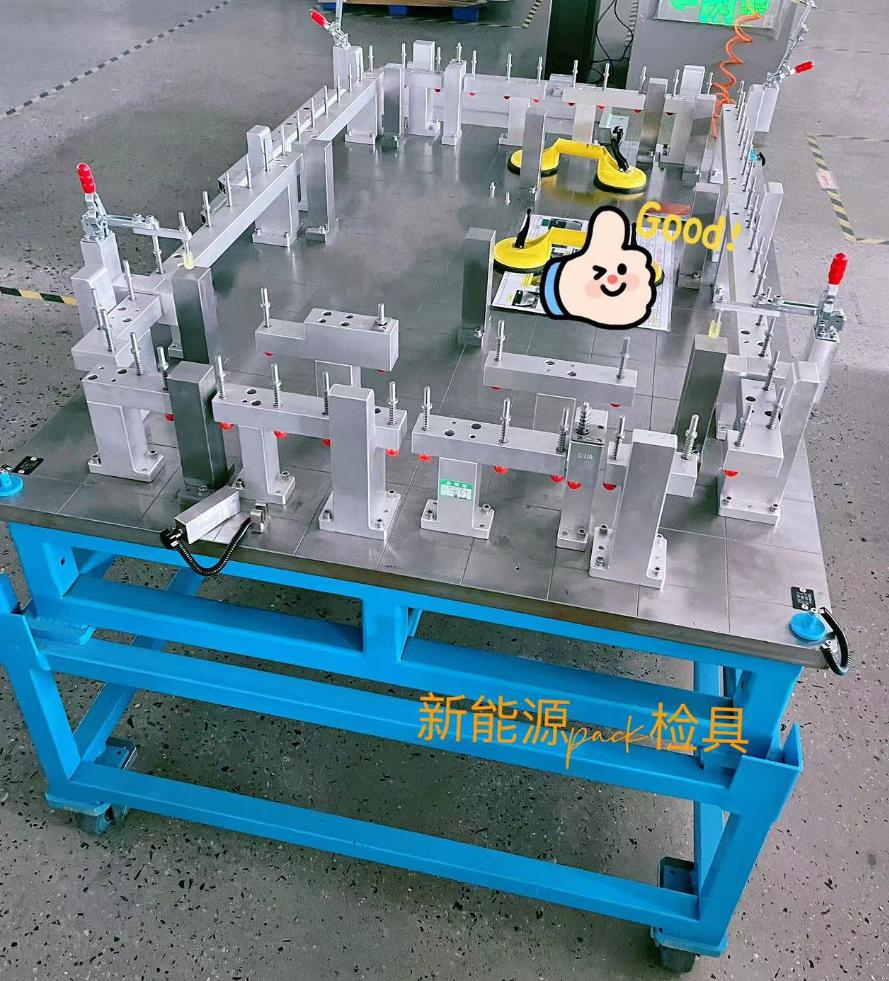

Non standard design of measuring tools and assembly fixtures

The non-standard design of measuring gauges and assembly fixtures is a customized design aimed at meeting the testing accuracy, assembly efficiency, or special process requirements of specific products. Its core lies in "targeted solutions to scenarios that cannot be covered by standardized tools". The following provides a detailed analysis from the aspects of design principles, processes, key elements, and industry applications:

1、 Core principles of non-standard design

Non standard design needs to balance functionality, economy, and reliability, following the following principles:

1. Guided by "product characteristics"

Adaptability priority: It is necessary to fully match the structure of the tested/assembled product (such as the contour of the measuring tool for irregular curved parts), material (such as avoiding deformation caused by rigid contact when testing soft plastic parts), and accuracy requirements (such as the positioning error of the aerospace part measuring tool should be ≤ 0.005mm).

Process compatibility: The assembly tooling needs to be adapted to the production line rhythm and operation mode (such as the tooling for automated production lines needs to be compatible with robot grasping trajectories, and manual assembly tooling needs to comply with ergonomics to reduce operator fatigue).

2. Balance between accuracy and cost

Precision grading design: High precision positioning components (such as precision guide rails and dial gauges) are used for critical dimension detection (such as bearing inner hole diameter), while non critical dimensions (such as shell edge fillet) can be simplified to pass stop gauge detection to reduce costs.

Economic solution: Priority should be given to using standard components (such as cylinders and linear guides) to reduce processing volume, and for complex structures, "welding+local precision machining" should be used instead of integral forging (such as large frame fixtures).

3. Safety and operability

Safety protection: Protective covers (such as infrared induction stop devices to prevent pinch injuries) should be designed for the parts of the assembly fixture that involve power sources (such as pneumatic and hydraulic); Sharp parts of the inspection tool need to be chamfered or wrapped.

Convenience of operation: The inspection tool needs to be designed with a quick clamping structure (such as buckles, magnetic positioning) to reduce workpiece loading and unloading time (target: single piece inspection time ≤ 30 seconds); The position and force of the tooling operating handle must comply with ergonomics (such as handle diameter 30-50mm, operating force ≤ 50N).

Please first Loginlater ~